Shell and tube type water cooled 35KW small capacity evaporator for evaporative cooling system

- Products Details

Quick Details

-

Brand Name: GREEFOUN

Model Number: RE35S5

Place of Origin: Hubei, China (Mainland)

Packaging & Delivery

- Packaging Details: High standard export wooden case package

- Delivery Detail: within 20days

Specifications

Stainless steel shell tube type water cooled dry evaporator

Stainless steel shell tube type water cooled dry evaporator is suitable for water cooled unit, water source heat pump, air cooled pump and air cooled heat pump unit. The product is applying for refrigerants of R22, R134a, R407C and R410A etc. The referigerating medium is for tap water, underground water, river water and sea water or brine, water and glycol solution, sulfate solution, etc. For heat exchange tube, copper pipe, copper nickel alloy tube, aluminum brass tube, stainless steel tube, etc. The shell raw material mainly are seamless steel tube, stainless steel pipe.

1, Heat exchange tube: four main tube type.

(1) ∅ within 3/8 "thread copper coil, it is mainly used for" U "type tube evaporator.

(2) ∅ within 1/2 "threaded straight copper tube, straight tube is mainly used for dry-type evaporator.

(3) ∅ 1/2 "corrugated straight stainless steel tube, straight tube is mainly used in food industry of dry evaporator.

(4) ∅ 5/8 "inside outside screw wing efficient copper tube, it is mainly used for air precooling industry dry evaporator.

2, shell raw material:

There are two of the major materials:

(1) # 20 seamless steel tube, mainly used for all kinds of load - more than 20 ℃ cold agent.

(2) 304/316 l stainless steel tube, it is mainly used for food and low temperature (below 25 ℃, higher than 40 ℃) of the refrigerant, 316 l can also be used for cooling load of the sulfate for industry.

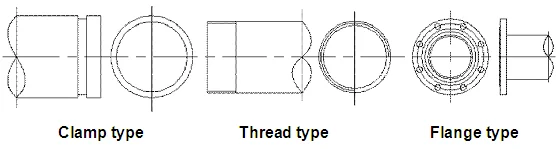

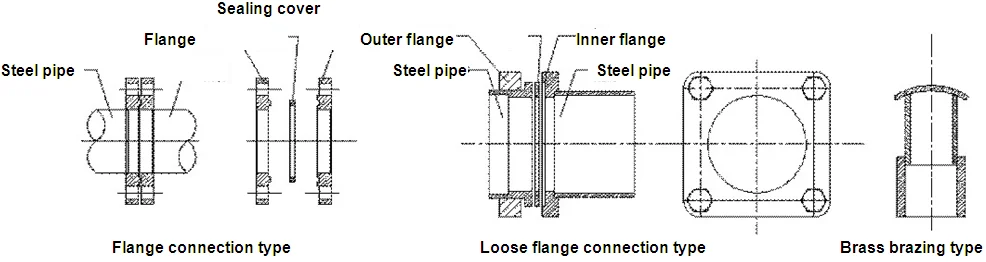

3, interface:

(1) load cooling interface main type of flange, thread and clamp type, as shown in figure. According to the demand of users.

(2) the refrigerant interface are mainly brass brazing type, loose flange connection type and tenon surface flange connection type, etc. As shown in figure. Can meet the requirements of users and habits to the greatest extent.

(3) the upper shell put empty set, lower set drainage outlet. Nozzle temperature is set on the mouth. Also can according to user requirements including water flow switch interface, antifreeze switch interface. Temperature measurement are mainly female mouth mouth and various rules of blind brass like ∅ 5/16, "3/8", 1/2 "∅ ∅, ∅ 5/8" brass or stainless steel tube, etc.

4, refrigerant gateway layout:

In and out of the refrigerant from the evaporator end, also can from both in and out of, convenient customer cloth tube.

5, refrigerant flow design.

Refrigerant can be designed into two processes, three processes and four processes. Can effectively guarantee the length of evaporation.

6, the length of the evaporator design.

Adjustments can be made according to the length of the condenser, evaporator length to ensure two configuration after the appearance is beautiful and satisfies the customer the installation space.

7, "U" type oil return pipe evaporator effect is good

The holes are gathering technology after make so the heat exchange efficiency is improved greatly. Under the condition of same refrigerating capacity, compared with the straight tube can greatly reduce the size of our evaporator, reduce the purchasing cost.

8, "U" type tube evaporator core body can be pulled out, convenient cleaning and maintenance.

9, the structure of the double "U" evaporator and the compressor straight tube can be symmetric arrangement

The advantages of convenient take over and appearance is beautiful, but the purchase cost increase.

In addition

The ordinary evaporator has rich experience in design and manufacture, for special evaporator, such as the food industry, industrial sulfuric acid, corrosion, acid and alkali resistance, salt tolerance) and low temperature series can also be designed and manufactured according to customer requirement. The normal operation of the above several evaporator were successful in all parts of the country.

Please pay special attention to customers:

1, biggest water flow and water flow is not greater than 1, otherwise it will affect the service life.

2, according to the annotation contributes presents installed correctly in and out of the gate, otherwise it will affect the effect and service life.

STRAIGHT SINGLE SERIES DRY SPIRAL BAFFLE PLATE EVAPORATOR CAPACITY: 310KW TO 680KW

Models |

|

|

RE310S10 |

RE360S12 |

RE420S12 |

RE470S12 |

RE540S14 |

RE620S14 |

RE680S14 |

Rated data Refrigerant R22 ti=12°C te=2°C tu=7°C Dts=5°C |

Qn |

KW |

310 |

360 |

420 |

470 |

540 |

620 |

680 |

Kcal/h(×103 ) |

267 |

317 |

361 |

404 |

464 |

533 |

585 |

||

Wn |

m3 /h |

53.3 |

62 |

72.2 |

80.8 |

93 |

107 |

116 |

|

Wm |

m3 /h |

68 |

70 |

81.7 |

100 |

105 |

140 |

145 |

|

Dpn |

bar |

0.43 |

0.43 |

0.35 |

0.46 |

0.41 |

0.47 |

0.49 |

Models |

RE310S10 |

RE360S12 |

RE420S12 |

RE470S12 |

RE540S14 |

RE620S14 |

RE680S14 |

|

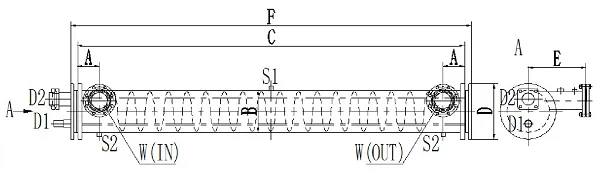

Dimension(mm) |

A |

140 |

140 |

150 |

150 |

150 |

170 |

170 |

B |

273 |

273 |

325 |

325 |

355 |

377 |

377 |

|

C |

2500 |

1690 |

2400 |

1500 |

2690 |

2690 |

2860 |

|

D |

360 |

360 |

406 |

406 |

440 |

460 |

460 |

|

E |

370 |

370 |

380 |

380 |

400 |

400 |

400 |

|

F |

2586 |

2586 |

2488 |

2586 |

2776 |

2776 |

2946 |

|

Vent |

S1 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

Outlet |

S2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

Connection |

W(DN) |

100 |

100 |

125 |

125 |

125 |

150 |

150 |

D1(mm) |

35 |

35 |

42 |

42 |

42 |

42 |

42 |

|

D2(mm) |

67 |

67 |

80 |

80 |

90 |

90 |

90 |

|

P(kg) |

296 |

380 |

398 |

442 |

459 |

654 |

669 |

|

Qn-rated refrigerating capacity Wn-cooling water flow Wm-maximum cooling water flow Dpn-pressure drop of recirculating cooling water Dts-overheat temperature |

||||||||

The shell side of the pressure design: normally design pressure is 1.0 MPa, tube side design pressure is 1.5 MPa. Heat pump tube side design pressure is 2.4 MPa. If you have special request, please contact technical department.

Company Information

Wuhan Qiaoxin refrigeration equipment co., Ltd. is a professional production and sales of shell and tube condenser, evaporator, heat transfer products of modern enterprise. In terms of technology, Qiaoxin always maintain the domestic leading position. Qiao xin has a strong sense of mission to the development of China refrigeration technology, using the most advanced refrigeration technology, realize the harmonious coexistence between man and nature.

Company show

Factory Show

Product Details

Scale: 101 - 200 People

Country/Region: China (Mainland)/Asia

Established:

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)

US 500-5,000 / Set 1 Set/Sets (Min.Order)